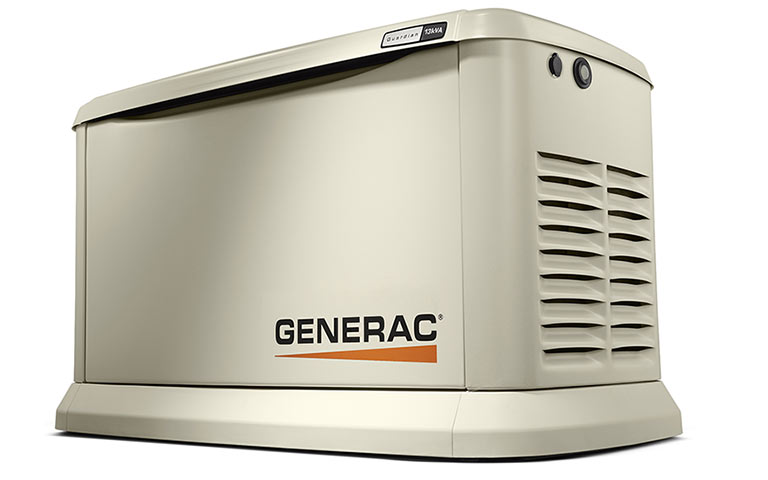

A Generac home backup generator senses a power outage, turns on automatically, and delivers backup power to your home. It will run until utility power returns – whether that’s two hours or two weeks.

With built-in smart phone capabilities, monitor the status of your generator from anywhere in the world using a smart-phone, tablet, or PC. The Generac runs at a lower RPM for a five or twelve minute test, is significantly quieter than other brands, and consumes less fuel.

The Generac is purpose-built for the rigors of power generation. It also requires fewer scheduled maintenance checkups than some competitor’s engines, and provides the reliability you need for the long run-times that emergency backup can require.

Pramac diesel generators are guaranteed to hold up to high quality standards and reliability with a specific design suitable for Emergency Standby and Continuous Power applications.

The modular design allow high flexibility on scope of supply, with a wide range of mechanical and electrical optional. We sell many options, from transportable to more permanent solutions.

We’ve helped thousands of South Australian’s tackle their power problems. Let’s get your power bills under control.